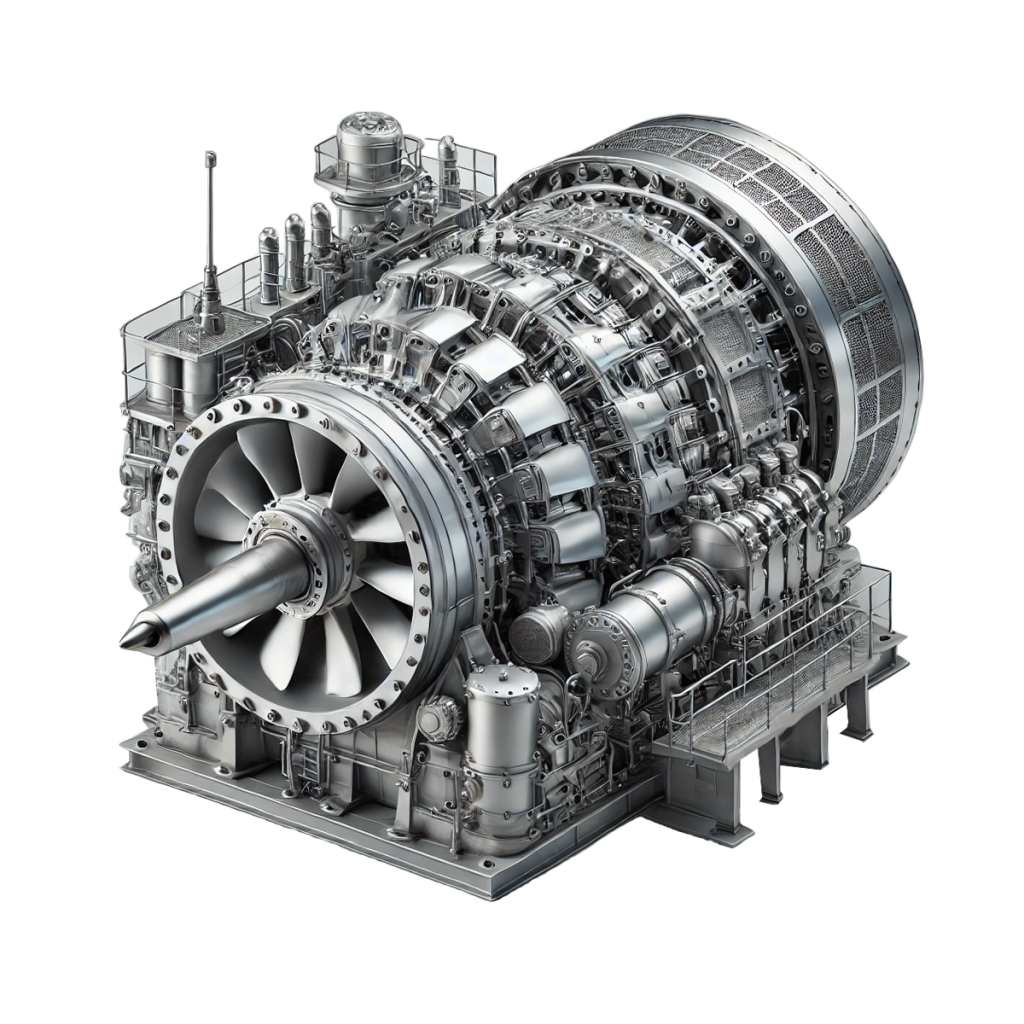

Extraction steam turbines are versatile and efficient turbines designed for power generation and industrial applications where both electricity and process steam are required. These turbines extract steam at intermediate stages for industrial or heating purposes, while the remaining steam is expanded to generate electricity. Widely used in combined heat and power (CHP) systems, extraction steam turbines provide flexibility, high efficiency, and reliability, making them essential for industries like power generation, chemical processing, and manufacturing.

In addition to extraction turbines, Steam Turbines are available in various configurations to meet diverse industrial needs. Condensing Steam Turbines are ideal for applications where maximum power output is required, as they condense the exhaust steam to increase efficiency. On the other hand, Back-Pressure Steam Turbines are commonly used in processes where steam is utilized directly after power generation, offering a practical solution for industries requiring both power and heat. Each type of turbine serves specific operational requirements, ensuring efficiency and optimal performance.

Extraction steam turbines are equipped with advanced features that enhance their performance and efficiency:

Extraction steam turbines are used across various industries to enhance energy efficiency and meet dual energy needs:

These turbines are used in power plants to generate electricity while extracting steam for district heating or industrial applications, improving overall energy efficiency.

In chemical plants, extraction turbines provide process steam for heating, drying, or chemical reactions, supporting critical industrial operations.

Extraction turbines supply steam for industrial processes like drying, sterilization, and mechanical drives, ensuring efficient energy use in manufacturing facilities.

In food processing, these turbines generate electricity while supplying steam for cooking, sterilization, and other operations, reducing energy waste.

Extraction turbines are used in the pulp and paper industry to provide steam for drying and electricity generation, supporting sustainable production practices.

Extraction steam turbines offer numerous benefits that make them indispensable for energy-intensive industries:

By extracting and utilizing steam for dual purposes, these turbines achieve superior energy efficiency compared to standalone power or steam generation systems.

Operators can adjust the pressure and flow of extracted steam to meet the specific energy demands of different industrial processes.

Extraction turbines reduce reliance on separate power and steam systems, lowering operational costs and enhancing energy utilization.

By maximizing energy use and reducing waste, extraction turbines help industries minimize their carbon footprint and achieve sustainability goals.

Engineered for demanding industrial applications, extraction turbines provide consistent performance and require minimal maintenance.

Proper installation and maintenance are critical for ensuring optimal performance and longevity of extraction steam turbines:

Enhance your energy systems with reliable Extraction Steam Turbines designed for dual-purpose efficiency and sustainability. Contact us today for a quote or visit our website to explore our range of turbine solutions tailored to your industry’s needs. Let us help you achieve cost-effective and sustainable energy with cutting-edge turbine technology.